A clean room is an environment that is strictly controlled in terms of temperature, humidity, and airborne particle contamination to prevent any impurities that may negatively affect products or manufacturing processes. Several industries rely heavily on clean rooms to maintain cleanliness and quality standards. The main industries that require clean rooms are as follows

1. Pharmaceutical and Biopharmaceutical Industry The production of medicines and biopharmaceuticals must occur in a completely sterile environment. As these products are used directly in the human body, contamination from dust, microorganisms, or chemicals can compromise their effectiveness or pose a danger to consumers. In manufacturing processes such as the preparation of active ingredients or sterile packaging, the highest level of cleanliness is required. Therefore, clean rooms in this industry must use HEPA filters for air purification and maintain a higher internal pressure than the surrounding environment to prevent external contamination.

![]()

2. Electronics and Semiconductor Industry Particle control is crucial in the electronics and semiconductor industry because components like computer chips or circuit boards are extremely delicate and small. Even a micron-sized particle can damage circuits or cause device malfunction. Clean rooms used in semiconductor manufacturing often need to maintain cleanliness at Class 1 or Class 10 levels according to ISO 14644 standards, meaning there should be no more than 10 particles per cubic foot for particles as small as 0.1 microns. HEPA or ULPA air filters are vital for maintaining cleanliness within these rooms.

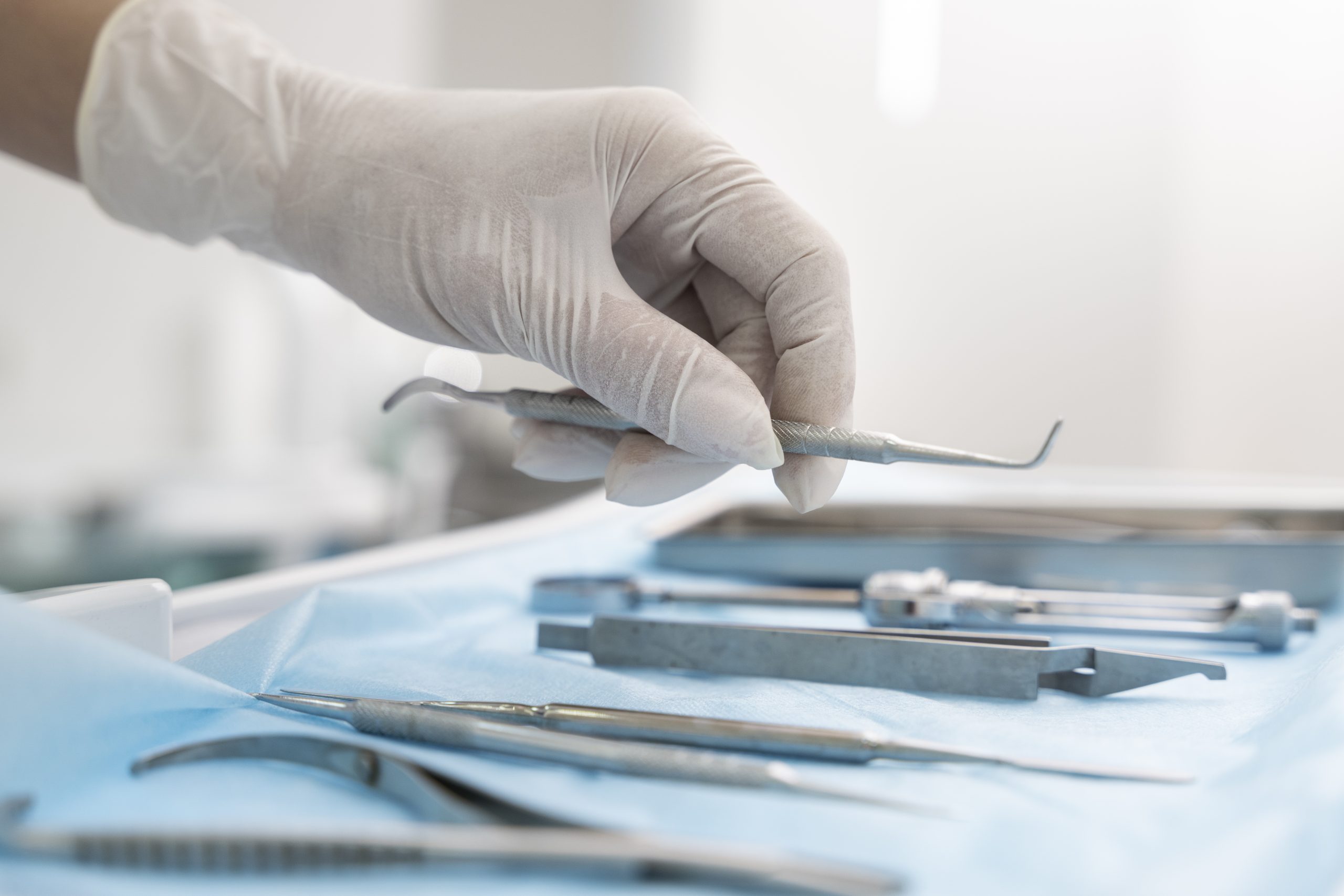

3. Medical and Medical Device Industry Medical devices, such as ventilators, pacemakers, or implants, must be manufactured under strict sterile conditions. These devices are often used in high-risk environments like operating rooms, where cleanliness is critical. Clean rooms in the medical device industry are designed with stringent quality control standards, including regular cleanliness checks and proper pressure maintenance to prevent contamination from external air. Additionally, operators must wear appropriate protective gear, such as gowns, masks, and gloves specifically for clean room use.

4. Aerospace and Automotive Industry The manufacturing of critical safety components, such as flight control systems or automated vehicle systems, must be done in dust-free environments to ensure precise functionality. Clean rooms in these industries not only control dust levels but also address electrostatic discharge (ESD), which can damage electronic components. Regular inspection and maintenance of clean room cleanliness help ensure that all components remain intact and fully functional.

5. Food and Beverage Industry While the food and beverage industry may not require as stringent clean room standards as the pharmaceutical industry, clean rooms are still used for producing products like dietary supplements or products requiring high purity to prevent contamination from dust, bacteria, and chemicals. In this industry, clean rooms contribute to safer production processes, especially for health-related products such as infant formula or dietary supplements. Additionally, controlling temperature and humidity in these rooms helps extend the shelf life of products.

Clean rooms play a vital role in many industries that need to maintain cleanliness and safety standards in production. Investing in clean rooms is a crucial factor that helps organizations produce high-quality products that meet standards and build trust with customers and consumers in the long term.

Order Clean Room Equipment Now – Click Here!